The Cascade Separator®- Advanced Sediment Capture Technology

The Cascade Separator is the newest innovation in stormwater treatment from Contech. The Cascade Separator was developed by Contech’s stormwater experts using advanced modeling tools and Contech’s industry leading stormwater laboratory.

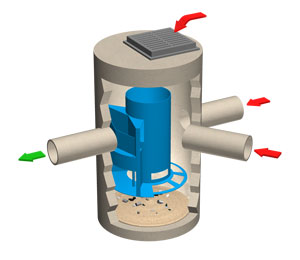

This innovative hydrodynamic separator excels at sediment capture and retention while also removing hydrocarbons, trash, and debris from stormwater runoff. What makes the Cascade Separator unique is the use of opposing vortices that enhance particle settling and a unique skirt design that allows for sediment transport into the sump while reducing turbulence and resuspension of previously captured material. These two factors allow the Cascade Separator to treat high flow rates in a small footprint, resulting in an efficient and economical solution for any site.

How the Cascade Separator Works

- 雨水enters the Cascade Separator through one or multiple inlets and/or a grate inlet.

- As water enters the unit, it impacts the center cylinder and is directed to two separate flumes.

- Water traveling through the opposing flumes enters the center chamber where vortices rotate in opposite directions and facilitate enhanced particle settling.

- As water swirls downward sediment settles into the sump and treated water exits through the outlet window and exits the system.

- When flows exceed the capacity of the flumes, the excess water flows over the flumes and exits the system without re-suspending or washing out previously captured pollutants.

- The system incorporates a partially perforated slanted skirt that equalizes the pressure between the storage and treatment zone while reducing the potential for scour. The skirt also allows transport of sediment and debris into the sump zone which improves ease of maintenance since all captured material can be removed through the center cylinder.